photocell wiring diagram pdf

Congratulations on your new 220V Photocell Wiring Diagram! This guide helps you understand and install your product safely and effectively. Explore the essentials of photocell wiring and ensure compliance with IEE regulations for a secure setup. Discover how to interpret diagrams, connect wires, and maintain Class II construction standards. Start your project with confidence using this comprehensive manual.

What is a Photocell?

A photocell, or photoelectric cell, is a light-sensitive device that converts light into electrical signals. It is commonly used in lighting systems to detect ambient light levels and control power distribution. Photocells are essential for automating lighting systems, ensuring energy efficiency by turning lights on or off based on daylight availability. They consist of a sensor and a control unit, with Class II construction ensuring safe, low-voltage operation. These devices are widely used in outdoor and industrial lighting, adhering to IEE wiring regulations for reliable performance. Understanding photocell functionality is crucial for effective installation and troubleshooting, as outlined in the wiring diagrams provided.

Why Use a Photocell Wiring Diagram?

A photocell wiring diagram is essential for safe and accurate installation of photocell systems. It provides a clear visual guide, ensuring components are connected correctly and efficiently. By following the diagram, you minimize the risk of electrical hazards and component damage. The PDF format ensures consistent and clear instructions, crucial for both professionals and DIY enthusiasts. It helps adhere to safety standards like IEE regulations, ensuring compliance and reliability. Whether for automatic lighting or security systems, a photocell wiring diagram is indispensable for successful setup and operation.

Key Components of a Photocell Wiring Diagram

A photocell wiring diagram includes essential components like live (brown), neutral (blue), and earth (yellow/green) wires, along with the photocell head and controller, ensuring Class II construction compliance.

Understanding the Photocell Kit

A photocell kit typically includes a photocell head and a controller, designed for Class II construction, ensuring safety and reliability. The kit provides a comprehensive solution for automating lighting systems, adhering to IEE wiring regulations. The photocell head detects light levels, while the controller manages the electrical circuit. Together, they enable seamless switching between power sources based on ambient light conditions. The wiring diagram included in the kit guides proper connections, ensuring compatibility with your electrical setup. Always verify the kit’s specifications and safety features before installation to guarantee optimal performance and compliance with local regulations.

Class II Construction and Safety Features

Class II construction ensures enhanced safety in photocell wiring, focusing on double insulation and protection against electric shock. These designs meet IEE wiring regulations, prioritizing user safety. Features include robust materials, thermal overload protection, and secure connections to prevent hazards. Earth connections are mandatory, and all components are fire-resistant. Installation by a licensed electrician is recommended to maintain safety standards. Always follow the manufacturer’s guidelines and local electrical codes. These safety measures ensure reliable operation and compliance with international standards, making Class II photocell systems a secure choice for various applications. Offline resources provide detailed diagrams and specifications for safe installations.

How to Read a Photocell Wiring Diagram

Understanding a photocell wiring diagram involves identifying components like the photocell, wires, and connections. Start by locating the power source and tracing through to the photocell and load. Use the diagram’s labels and color codes to recognize live (brown), neutral (blue), and earth (green/yellow) wires. Ensure compliance with IEE regulations and Class II safety standards. Refer to the PDF manual for symbols and connections, and consider consulting a licensed electrician for installation. This guide helps you interpret both schematic and wiring diagrams effectively for safe and correct setup.

Identifying Wires and Connections

Identify wires and connections by referring to the photocell wiring diagram. Live (brown), neutral (blue), and earth (yellow/green) wires are typically marked. Ensure connections match the diagram, with Lo (switched live) linked to the load. Consult the manual for specific wire color codes and functions. For NEMA sockets, follow the diagram to connect correctly. Always verify connections before powering up. Safety is crucial, so consider hiring a licensed electrician. Adhere to IEE wiring regulations for a secure setup. Double-check all connections to avoid errors. Turn off the power supply before starting work. This ensures compliance and safety.

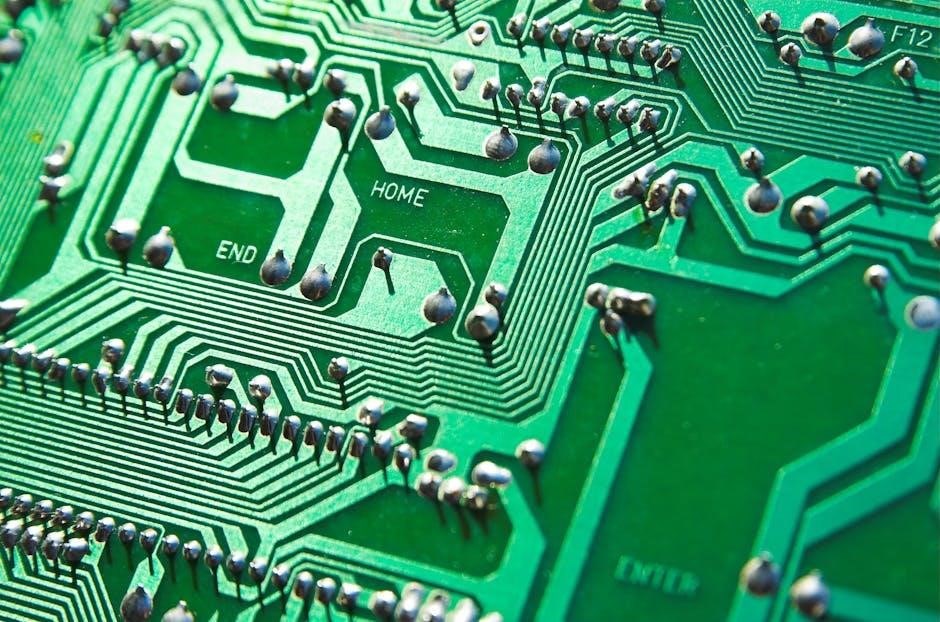

Interpreting Schematic and Wiring Diagrams

Understanding schematic and wiring diagrams is crucial for safe and effective photocell installations. These diagrams provide visual representations of components, such as photocells, wires, and connectors. Symbols and color coding differentiate between live, neutral, and earth wires. Begin by identifying the photocell’s input and output terminals, then trace the circuit to ensure proper connections. Pay attention to Class II construction details, which emphasize safety. Always verify compatibility with IEE wiring regulations. For clarity, refer to downloadable PDF resources, which often include detailed diagrams and step-by-step instructions. Offline access ensures convenience for hands-on installations. By carefully interpreting these diagrams, you can avoid errors and ensure reliable operation of your photocell system.

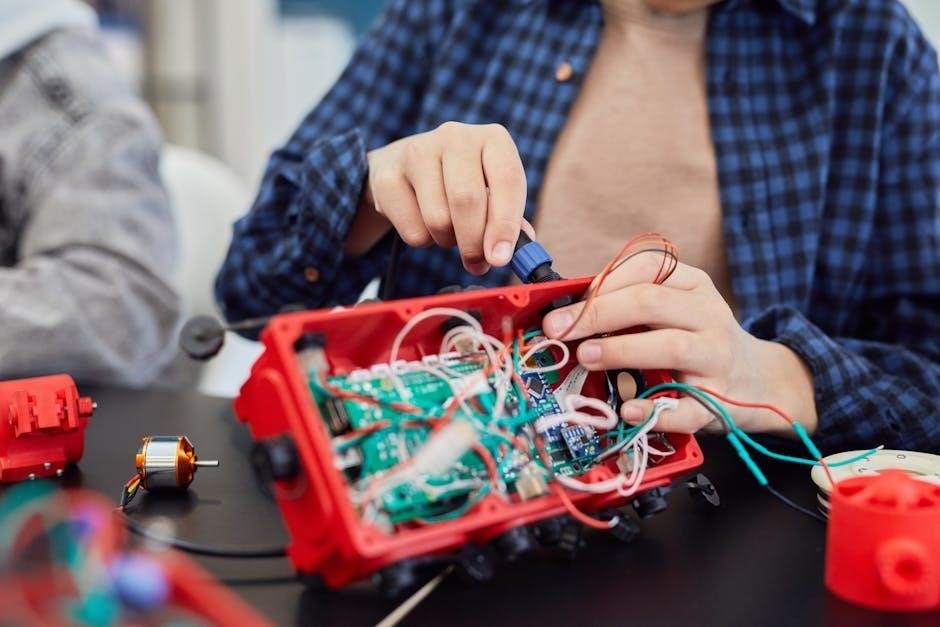

Step-by-Step Wiring Instructions

Follow the wiring diagram to connect wires correctly. Ensure the earth connection is secure. Connect live, neutral, and load wires as indicated. Always hire a licensed electrician for safe installation and IEE compliance.

Preparing the Photocell for Installation

Before installing your photocell, carefully unpack and inspect the kit to ensure all components are included. Verify the presence of the photocell sensor, wiring diagram, and mounting hardware. Familiarize yourself with the Class II construction specifications to guarantee safety and compliance with IEE regulations. Review the wiring diagram to understand the connections between the photocell, power supply, and load. Mount the photocell in a location with optimal light exposure, ensuring it is securely fastened. Double-check the wiring diagram to confirm proper connections, such as live (brown), neutral (blue), and earth (yellow/green) wires. Ensure all connections are tight and insulated before powering up the system.

Connecting Wires to the Photocell Sensor

To connect wires to the photocell sensor, start by identifying the live (brown), neutral (blue), and earth (yellow/green) wires. Consult the wiring diagram PDF for specific connections. Ensure the live wire is connected to the appropriate terminal, typically controlled by the photocell for automatic switching. Secure all connections tightly using wire nuts or connectors to prevent loose wiring. Always turn off the power supply before starting and adhere to IEE regulations. If unsure, consider consulting a licensed electrician for safe and correct installation.

Safety Recommendations and Precautions

Ensure installation by a licensed electrician and adhere to IEE Wiring Regulations. Always turn off power before starting work. Properly ground the system to avoid electrical hazards.

Installation by a Licensed Electrician

Installation of your photocell wiring should always be performed by a licensed electrician to ensure safety and compliance with IEE wiring regulations. The product manual explicitly recommends hiring a qualified professional, especially for 220V systems, to avoid potential hazards. Improper wiring can lead to electrical shocks, fires, or system malfunctions. A licensed electrician will ensure your setup meets Class II construction standards and adheres to all safety protocols. They will also interpret the wiring diagram accurately, connecting live, neutral, and earth wires correctly. DIY attempts are discouraged due to the complexity of the wiring and the risks involved. Always prioritize professional installation for reliability and compliance.

Adhering to IEE Wiring Regulations

Adhering to IEE wiring regulations is crucial for safe and compliant photocell installations. Ensure your setup meets Class II construction standards, minimizing shock risks. Licensed electricians should handle installations to guarantee adherence to these regulations. Always follow the wiring diagram’s guidelines to avoid electrical hazards. Non-compliance can lead to safety issues or legal consequences. Verify wire colors (Live — Brown, Neutral — Blue, Earth — Yellow/Green) and ensure proper connections. Turn off power before starting work. Refer to the wiring diagram for specific instructions and maintain compliance throughout the process to ensure a secure and reliable photocell system. Safety and regulatory adherence are non-negotiable.

Downloading and Using Photocell Wiring Diagrams

Download photocell wiring diagrams as PDF files for offline access. These resources provide detailed instructions and visuals, ensuring safe and correct installations. Print or save them for easy reference during projects.

Free PDF Resources for Photocell Diagrams

Access comprehensive photocell wiring diagrams in PDF format for free. These resources provide detailed schematics and installation guides, ensuring safe and proper connections. Download diagrams for models like the GTR208 reflective photocell or GTR058 controls from trusted sources such as richmondau.com. These PDFs are ideal for offline reading and printing, offering clear instructions for wiring and setup. Utilize these resources to understand how to connect wires, interpret circuits, and maintain compliance with safety standards. Perfect for professionals and DIY enthusiasts, these free PDFs simplify the installation process of photocell systems, ensuring reliability and efficiency in your projects.

Offline Reading and Printing Options

For convenience, photocell wiring diagrams are available as downloadable PDF files, enabling offline access. This format ensures reliability without internet connectivity. Users can print diagrams on standard paper for easy reference during installations. Offline reading allows technicians to review schematics in any setting, enhancing workflow efficiency. Printed copies can be annotated for specific project needs, ensuring clarity. Always verify that downloaded diagrams comply with current IEE wiring regulations for safety and compliance. This feature is particularly useful for electricians working in remote locations or areas with limited internet access, ensuring uninterrupted access to critical installation guidelines.

Leave a Reply

You must be logged in to post a comment.